Your Cart is Empty

Products - by Industry

Products - by Brand

Parkway - Water Treatment

Fieldpiece Gauges Maintenance Guide

February 18, 2024 3 min read

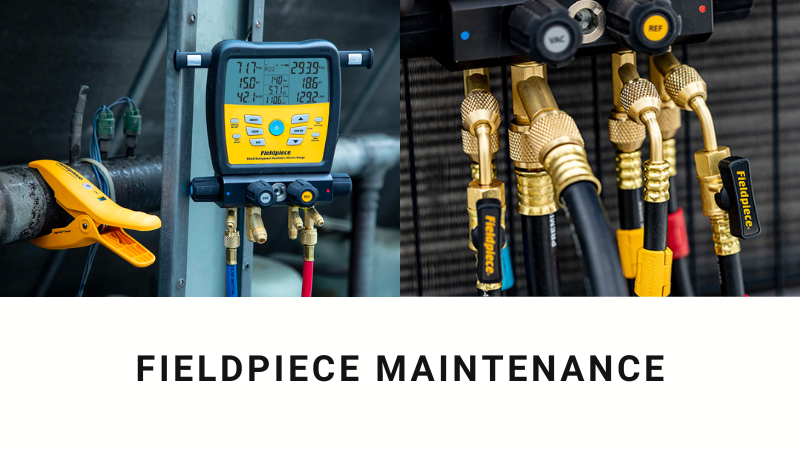

Fieldpiece Gauges Maintenance Guide: Ensuring Reliability and Accuracy

Maintaining the accuracy and longevity of Fieldpiece gauges is crucial for professionals in the HVAC industry. These precision instruments are vital for diagnosing system performances and ensuring that installations and repairs meet stringent standards. Regular maintenance of Fieldpiece gauges can prevent inaccurate readings that could lead to costly errors or system failures. It is therefore imperative for technicians to understand the appropriate care and handling of these tools to ensure their reliable performance.

Practical maintenance of Fieldpiece gauges involves routine checks and cleanliness that are essential for their optimal operation. Simple actions such as storing gauges in protective cases when not in use, avoiding exposure to extreme temperatures, and keeping the sensors clean can greatly extend their useful life. For more technical maintenance, it is important to periodically calibrate the gauges to maintain measurement accuracy. Ensuring these practices are part of a regular maintenance routine will undoubtedly contribute to the precise operation of Fieldpiece gauges.

Key Takeaways

- Regular maintenance extends the life and accuracy of Fieldpiece gauges.

- Proper storage and handling are fundamental for gauge performance.

- Periodic calibration is essential to maintain measurement precision.

Fundamentals of Fieldpiece Gauge Maintenance

Proper maintenance of Fieldpiece gauges is critical to ensure accurate measurements and long-term reliability. This section examines the core practices indispensable to maintaining Fieldpiece gauges effectively.

Understanding Your Fieldpiece Gauges

Fieldpiece gauges are sophisticated instruments designed to measure system pressures and temperatures accurately, which are vital for diagnosing and servicing HVAC systems. They typically consist of a digital or analogue display, pressure sensors, and temperature probes. Understanding the components and their functions enables technicians to perform maintenance correctly and recognise when servicing is required.

Routine Inspection Procedures

Regular Checks: Technicians should conduct routine inspections of Fieldpiece gauges, looking for signs of wear and tear such as cracked displays, worn seals, or damaged connectors.

- Visual Examination: Check for physical damage or contamination.

- Performance Assessment: Monitor gauge readings for signs of inconsistency or drift.

Cleaning: Keeping the gauges clean is essential:

- Use a soft, damp cloth to wipe the case.

- Clean the sensor ports with compressed air.

- Avoid harsh chemicals that can damage sensitive components.

Calibration Essentials

Calibration of Fieldpiece gauges is necessary to ensure that measurements remain within the manufacturer's specified tolerances. Recalibration should be done periodically, according to the manufacturer's recommendation, or when a gauge's performance is in doubt.

- Frequency: Fieldpiece gauges typically require recalibration annually, although more frequent calibration may be needed based on usage.

- Procedure: Follow the manufacturer’s step-by-step calibration process carefully to ensure accuracy. Use only certified calibration equipment verified to national standards.

Advanced Maintenance Techniques

For Fieldpiece Gauges to function correctly they require routine maintenance. Advanced techniques ensure precision, longevity, and consistent performance.

Leak Testing and Repair

To identify leaks in Fieldpiece Gauges, one should use a soapy water solution applied to all connections while the gauge is pressurised. Bubbles forming indicate a leak. Once a leak is detected, shut off the pressure and tighten the fittings or replace seals as necessary.

Sensor Servicing and Replacement

Sensors need periodic servicing to maintain accuracy. Calibration is crucial and should only be carried out using the manufacturer's recommended equipment. Should a sensor fail, it must be replaced with an OEM part to ensure compatibility and reliability.

Battery Management and Troubleshooting

Effective battery management is key for uninterrupted service. Fieldpiece Gauges should be stored with batteries removed to prevent corrosion. If a gauge is not powering on, first check the battery terminals for cleanliness and contact. Use a multimeter to test battery voltage; replace batteries if below the operational threshold.

Questions? Give us a call

1300 525 120

Request for Quote

TO ADD MULTIPLE ITEMS TO YOUR QUOTE, PLEASE FILL QTY FIELD THEN CLICK ON "ADD TO QUOTE"